Thin-film palladium membranes

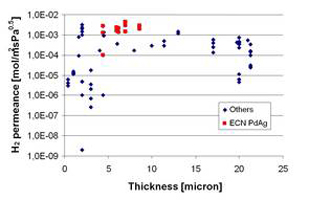

An essential element of the Hysep technology is the use of thin-film palladium membranes. A palladium membrane separates high-purity hydrogen from a mixture of gasses. Hydrogen passes through the palladium layer which is impermeable to other gasses. The thickness of the palladium layer is a key issue. As the palladium layer becomes thinner, the hydrogen flux becomes higher and membrane cost lower. The TNO palladium membrane layer in the Hysep module has a thickness as low as 3-9 µm, a substantial improvement over current commercially available palladium membranes which are based on self-supporting metals foils with a thickness of 20-100 µm.

Low cost membrane fabrication

To make these membranes TNO has developed technology to apply a very thin layer of palladium on a ceramic support tube. In this way the excellent hydrogen selectivity of the palladium layer and the robustness of a ceramic support tube are combined.

In all aspects of membrane technology development, focus has been on low-cost solutions. Using thin layers reduces the amount of palladium on a membrane to a minimum. Because of the higher flux in using thin-films, the number of membranes required to separate the same amount of hydrogen is much lower. This has a large impact on cost. Also in the selection of the ceramic support system and manufacturing steps cost has been leading. Although the support tube is a high-tech product requiring unique expertise to manufacture, it is based on low-cost ceramic tubes. In producing membranes based on these tubes only production methods are used which enable scale-up to cost-effective high-volume industrial fabrication.

High membrane performance

Key characteristics of the membranes are the hydrogen flux, selectivity and lifetime. These will depend on the specific process, most importantly on the pressure at which the hydrogen containing mixture is available, the gas composition and the presence of contaminants. Lifetimes of several thousands of hours have been shown under different conditions. Purities which can be reached range from 99.5% to 99.995% in a single step depending on the initial composition.

TNO can make Pd coated porous tubes up to a length of 90 cm. Although the technology of choice uses ceramic support tubes, we are able to deliver modules based on stainless steel tubes as well. The Pd membranes are closed by a patented leak tight sealing (International patent WO01/63162A1) at one end and can resist pressure differences of at least 30 bar with the highest pressure on the outside of the tube.